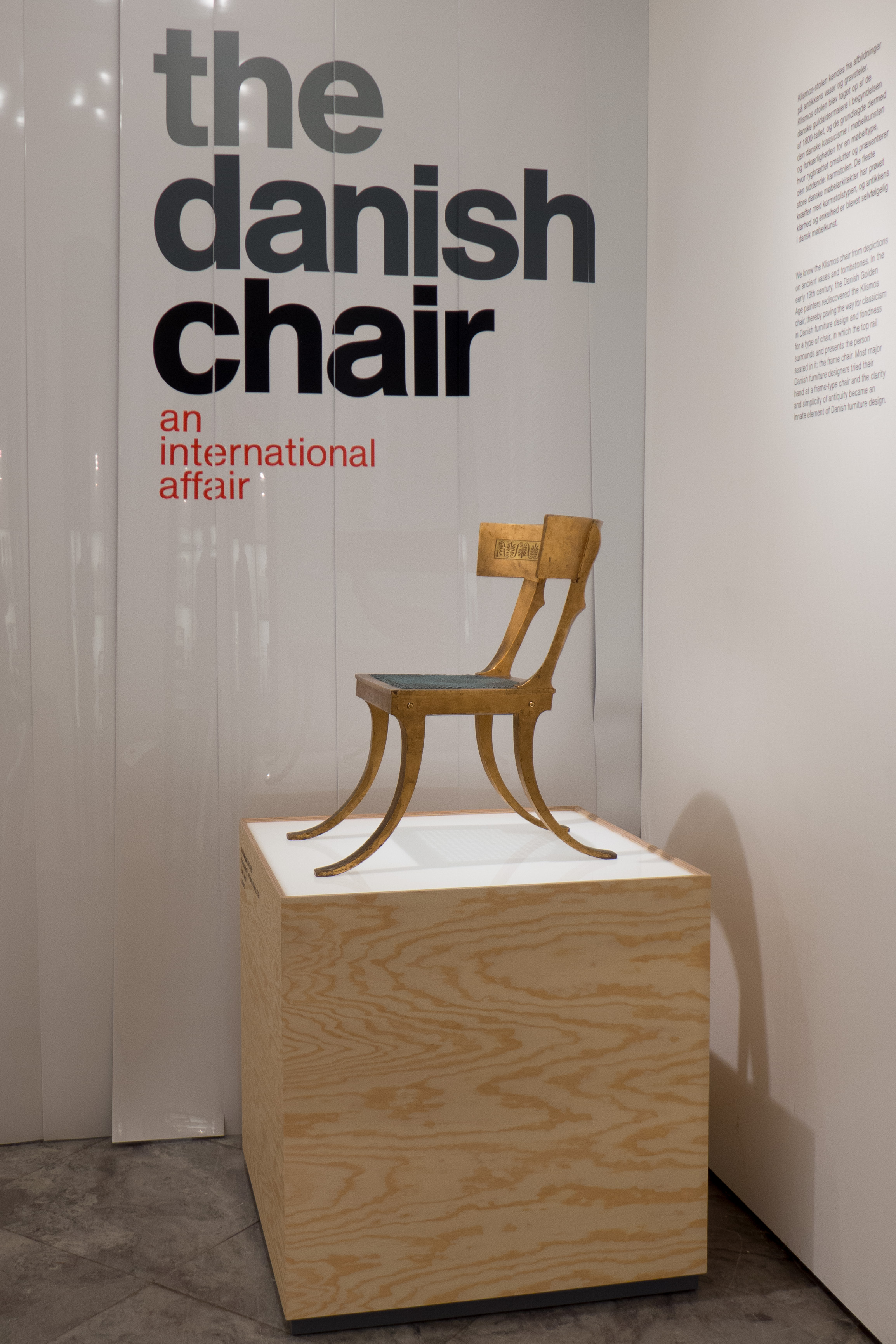

Designmuseum Danmark have just published a book about chairs in the collection of the museum. Most of the chairs are from the 20th century and most are Danish although there are several chairs that were made in the 19th century - an English Windsor Chair, an American Shaker Chair and Chinese chairs - that have been included because their forms of construction influenced Danish designs - and there are some modern international designs including chairs from England, Italy, Austria, Germany and the USA that help to set the Danish furniture in a wider context.

Essentially, the book takes the form of a catalogue with separate entries for nine stools and for 104 chairs with each on a double-page spread although for 31 of these the entries continue over to a second double-page that is used for historic photographs of the chair or for reproductions of working drawings.

Descriptions for each chair are succinct with most of the entries just over a hundred words although several are shorter and only two of the chairs have a text that goes into a second paragraph.

This certainly gives the book a clear and tight discipline.

Because this is not a continuous narrative text, it reads more like good museum labels and that is appropriate as the book accompanies a new gallery for the collection of chairs in the museum that was designed by Boris Berlin and completed in 2016.

With a relatively unusual format - the book is 150 mm wide and 270 mm high - the initial impression is that this is a handbook or even a pocket guide but at 32 mm thick and printed on heavy, good-quality paper this is a hefty book so would need a large pocket.

Although it is tall and narrow, the double spread of facing pages gives a good and attractive square format. My only criticism of the book is that several interesting historic photographs and illustrations that have been placed across two pages are broken and distorted by a tight gutter.

Christian Holmsted Olesen, the author of the book, is a curator at the museum and wrote a seminal book on the work of the Danish furniture designer Hans Wegner - Wegner - just one good chair that was published as the main catalogue for an exhibition at Designmuseum Danmark in 2014. His introduction here is short but wide ranging and puts chair design in the much wider context of Danish design in the 20th century.

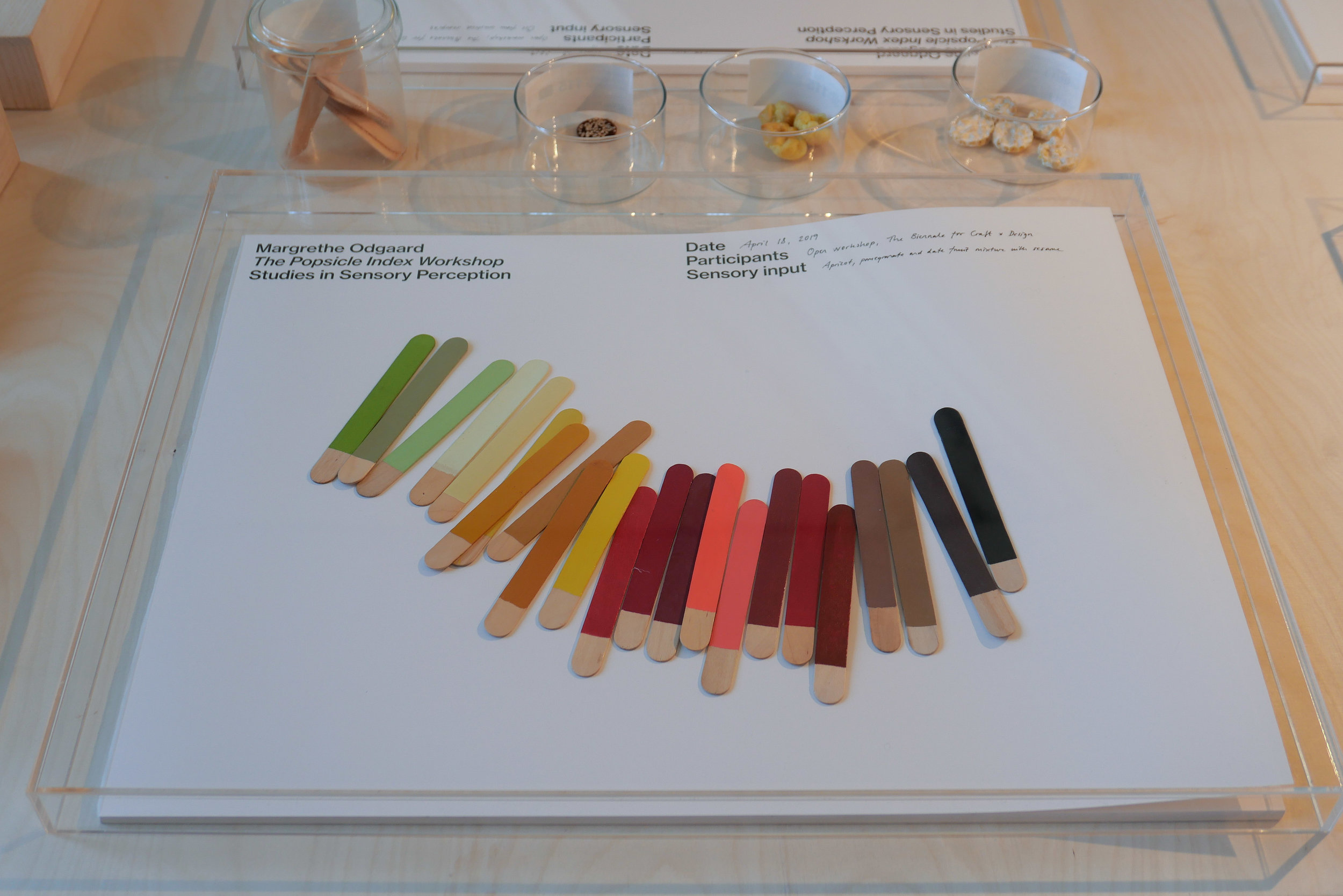

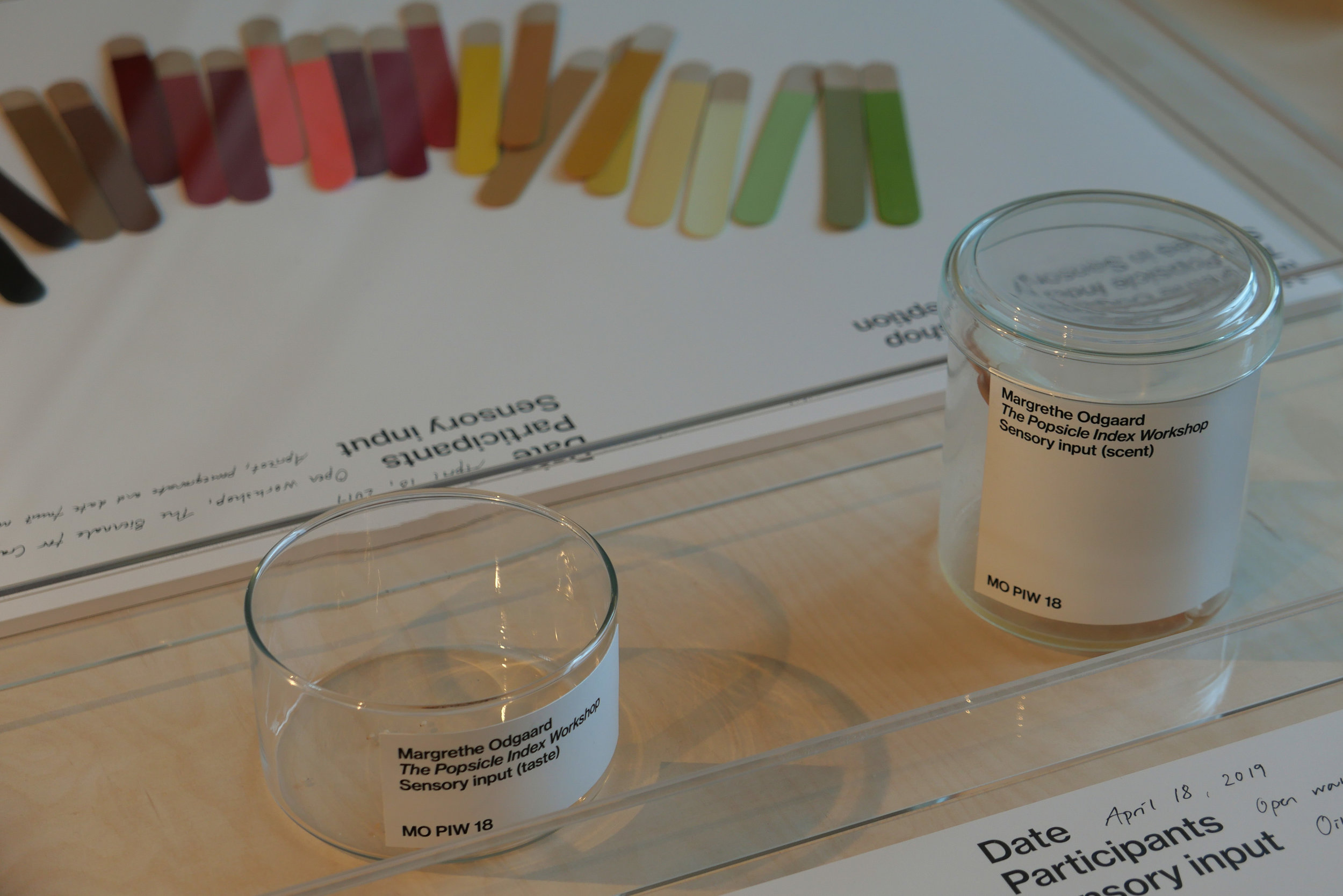

His aim is to show "how the so-called Golden Age of Danish furniture design was shaped by the study and refinement of historical furniture types," so the chairs in the book are not presented chronologically or by country but grouped by type … by form of construction. Types here are slightly different from the categorisation of form types in the museum gallery - presumably to be less specifically Danish and slightly more obvious for the foreign reader. The most straightforward change is that Shaker chairs, Chinese chairs and steam-bent chairs and the Klismos type of chair and Round Arm chairs - all types specified in the museum display - have been re-arranged in the book and those groups given new names. There is a new category for "Peasant chairs" - here including the influential Shaker chair from the collection and the well-known Church Chair by Kaare Klint and the People's Chair by Børge Mogensen - and the rest are divided between Bentwood chairs and Frame chairs.

In the book the categories for form or type are:

Folding stools and chairs

Low easy chairs

Peasant chairs

Bentwood chairs

Frame chairs

English chairs

Windsor chairs

Shell chairs

Cantilever chairs

Each section is prefaced by a list of the specific chairs of that type or of that form along with the useful outline sketches that were developed for information panels in the exhibition.

The book concludes with profiles of nine prominent and influential Danish designers …. Kaare Klint, Mogens Koch, Ole Wanscher, Børge Mogensen, Hans Wegner, Finn Juhl, Arne Jacobsen, Poul Kjærholm and Verner Panton.

Again, these are short accounts but authoritative - presumably for the general reader who wants more information for context - and finally there is a short but again useful list of recommended books for finding out more.

review of the museum chairs

The Danish Chair an international affair

by Christian Holmsted Olesen

Designmuseum Danmark with Strandberg Publishing 2018

layout and cover design: Rasmus Koch Studio

Designmuseum Danmark

Strandberg Publishing

Rasmus Koch Studio