At the Space10 gallery in the Meat Market, there is a small but interesting exhibition about a new furniture or light-weight construction board made from recycled materials.

Sometimes it is worth looking back at the basic problem before looking at the solution. Some readers will groan and say it is obvious but it helps to look at the problem in order to judge the solution being offered.

People have used timber for building and for making furniture for thousands of years so the techniques of working with wood are well known and well mastered and timber can be - although it is not always - a sustainable material.

The problem, if it is again stating the obvious, is that timber comes in tree sized and branch and tree trunk shaped pieces and people want large (wide and long) and flat and stable materials for, for instance, table tops and cupboard doors.

Wood can be joined by making a raft with narrow strips but this involves glue or pegs or joins such as tongue and groove over long lengths and these composite boards can still twist or warp if the wood is not well seasoned and the boards usually need a thin surface layer such as a veneer to cover all the joins. Block board, of one form or another, as a relatively cheap furniture board, has been manufactured for decades but is heavy.

Thin layers of wood stuck together with glue (plywood) can be stable but works best with good-quality timber ‘peeled’ into these thin layers and again it is heavy to work with and needs some form of edging strip and, with thinner plywood, some form of supporting frame or structure and the edge and cut lines splinter or are jagged if the cutting tools are not sharp.

An alternative is to use wood chips or wood fibre pressed together with glue and often with a wood veneer on the surface but boards are also made with a thin plastic coat (so now questionable) and marketed under different names such as Conti Board. The glues used in the past have been dubious and, again, the material can chip or split or snap when not cut in the right way or if weights are dropped on, say, the end of a table top, and, once damaged, the board absorbs damp or water and swells and disintegrates.

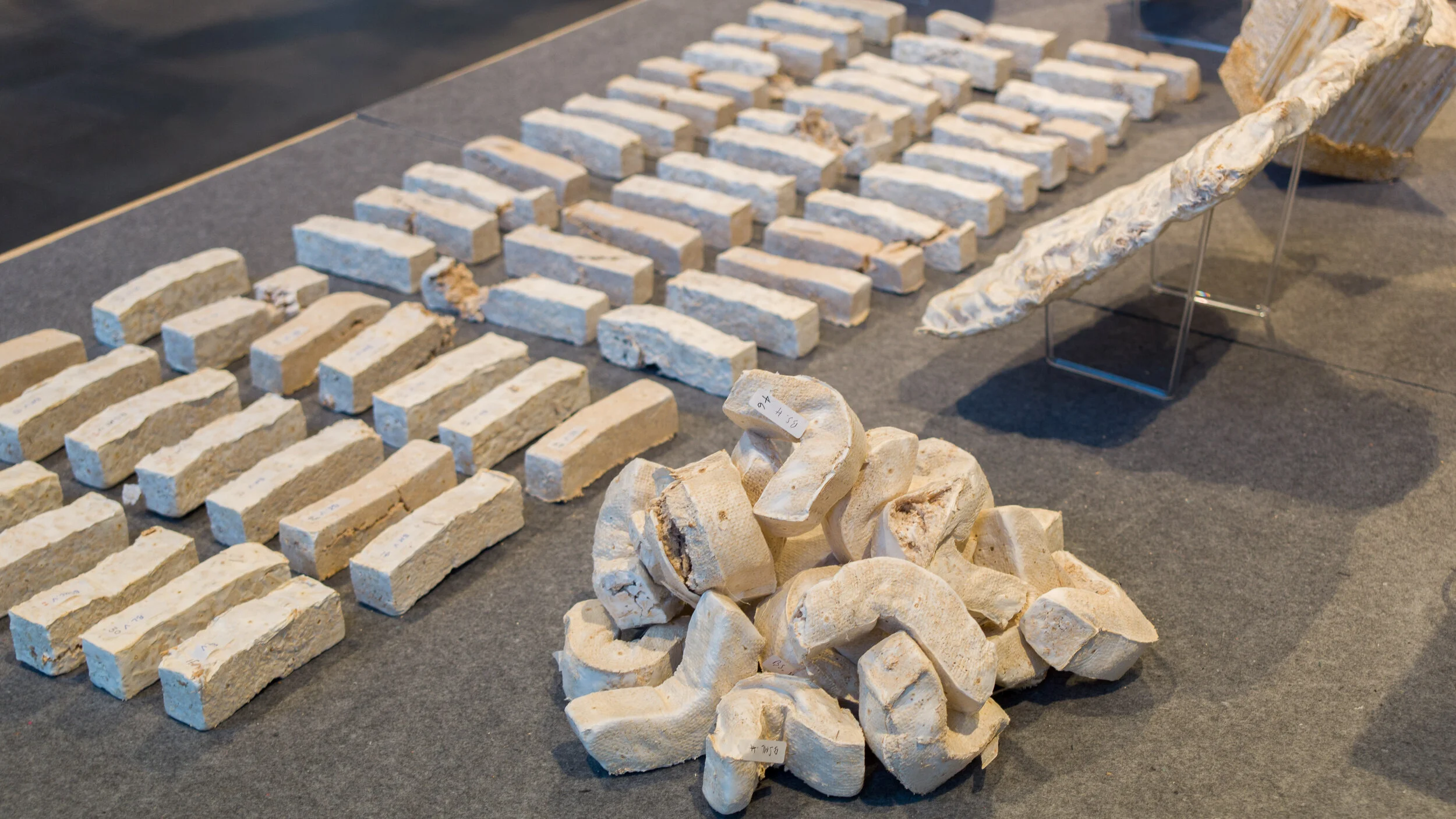

The new board shown at Space 10 is basically a new technique of manufacture. It uses recycled paper, tightly pressed together, to create what is, to put it crudely and very unfairly, corrugated paper on steroids. The board is wide and very smooth on the surface so can be painted with little extra preparation and presumably it could be self coloured. It has a hollow construction with angular longitudinal spaces so, as with well-established fibre boards, the problems are that if it is cut to make shorter pieces then it needs to be cut precisely and with sharp tools and the open edge has to be finished with an edging strip.

It is light weight and there is an ingenious new system with metal joining pieces made from recycled aluminium. Conti Board, for instance, can be used with small interlocking plastic blocks in two parts with each fitted to the main and the cross piece with screws and then the blocks clipped and bolted together. These are relatively strong but are better if they are fixed precisely and are ugly so better hidden from sight on the underside or within the furniture being made. That is not a problem with the Space 10 system where the joins are internal and hidden once the piece is assembled.

The new board shown at Space 10 is shown with photographs of furniture designed by Ransmeier Inc.

By the nature of the board, these are starkly simple forms but it is clearly a good light-weight material and with the right designs could make furniture that can be disassembled and moved easily but again loading, for instance if the board is used for shelves or a table top, could be a problem along with impact damage.

As always, there is a balancing act, in any argument about sustainability …. cheap and simple is good but at what point does cheap and simple become cheap and easily thrown away and replaced and that is now more difficult to justify. At one extreme, an expensive table top with mahogany veneer can have chips and scratches lovingly repaired over centuries of use that can, in part, justify the initial investment and at the other extreme you have a flat table top between trestles where the top can be thrown away and replaced immediately it is damaged. The marketing trick for IKEA is finding a material and techniques of construction that fit somewhere between the two.

Technology and the furniture of tomorrow continues at Space10 until 27 February 2020